Custom Tooling, Design & Engineering Solutions

Our Solutions

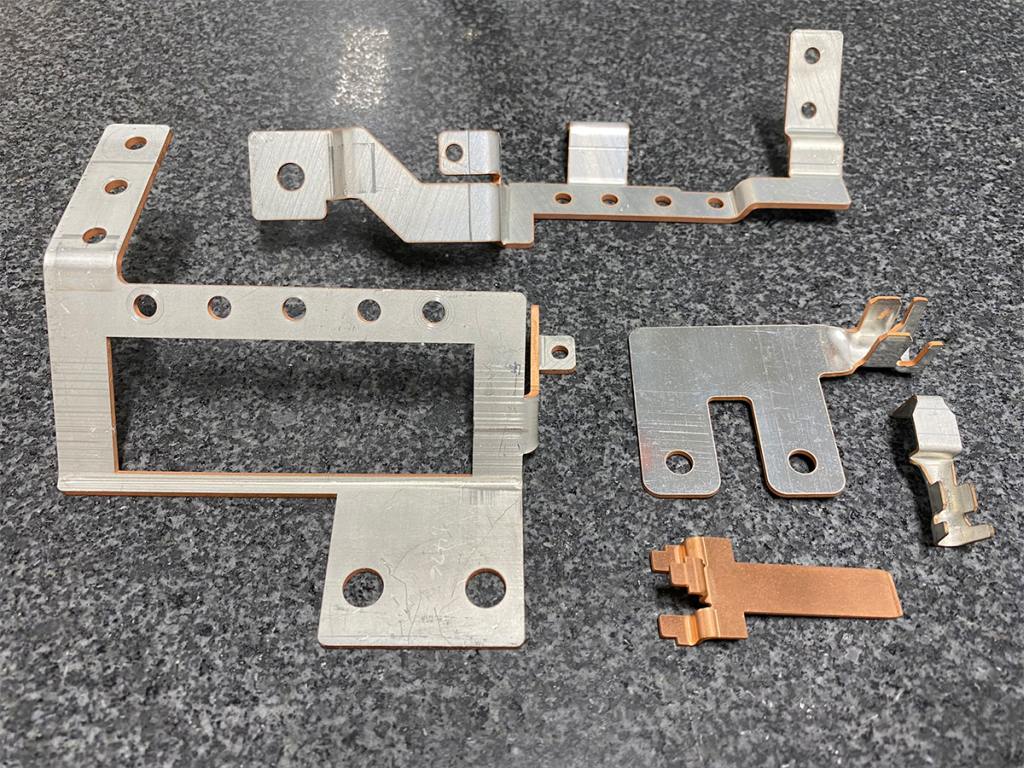

High quality, cost competitive tooling and design solutions for the stamping, molding, and custom components industries. Electrical terminal, buss bar and stamping related prototypes.

Project Management. Engineering changes, 3D and 2D CAD work.

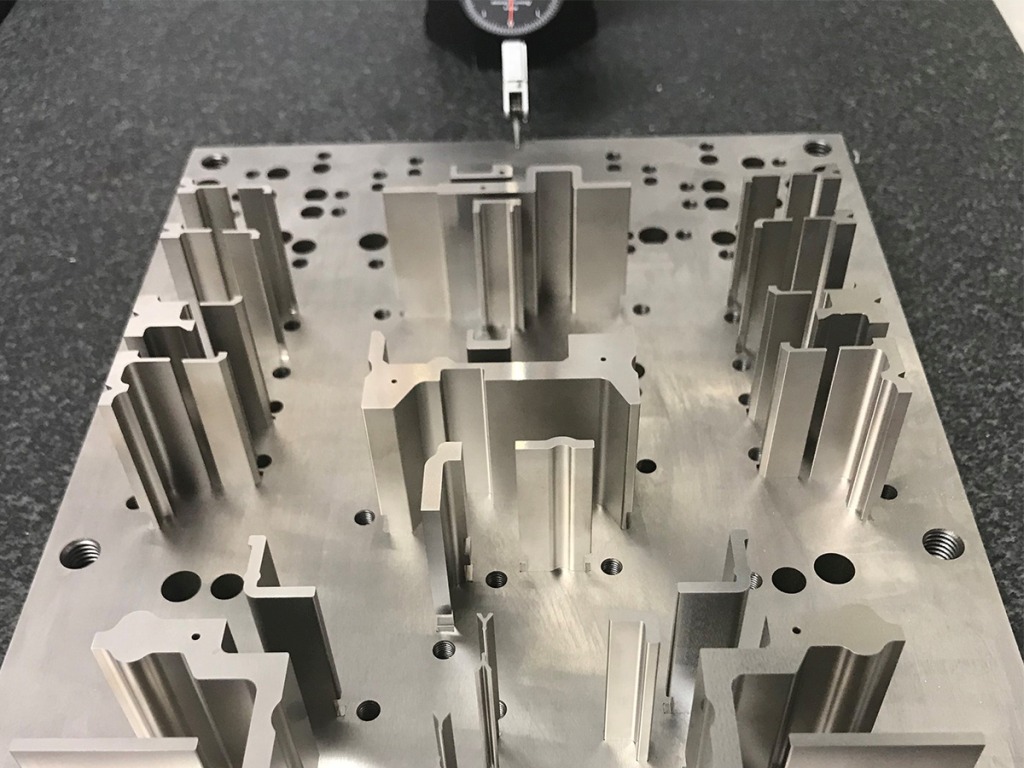

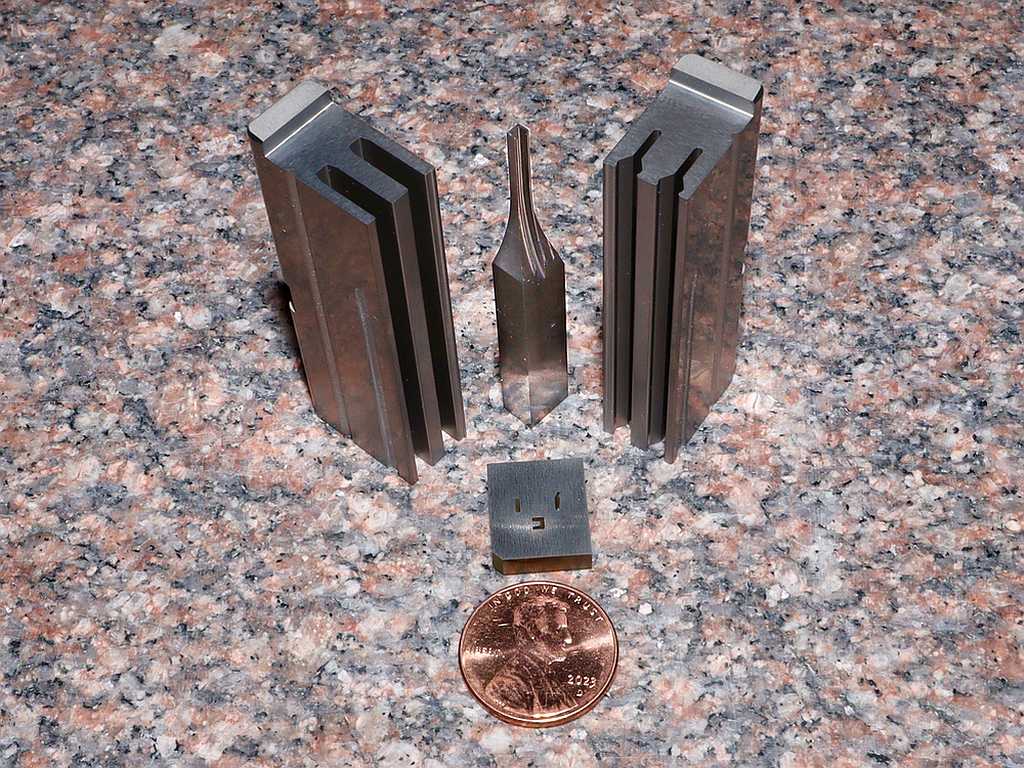

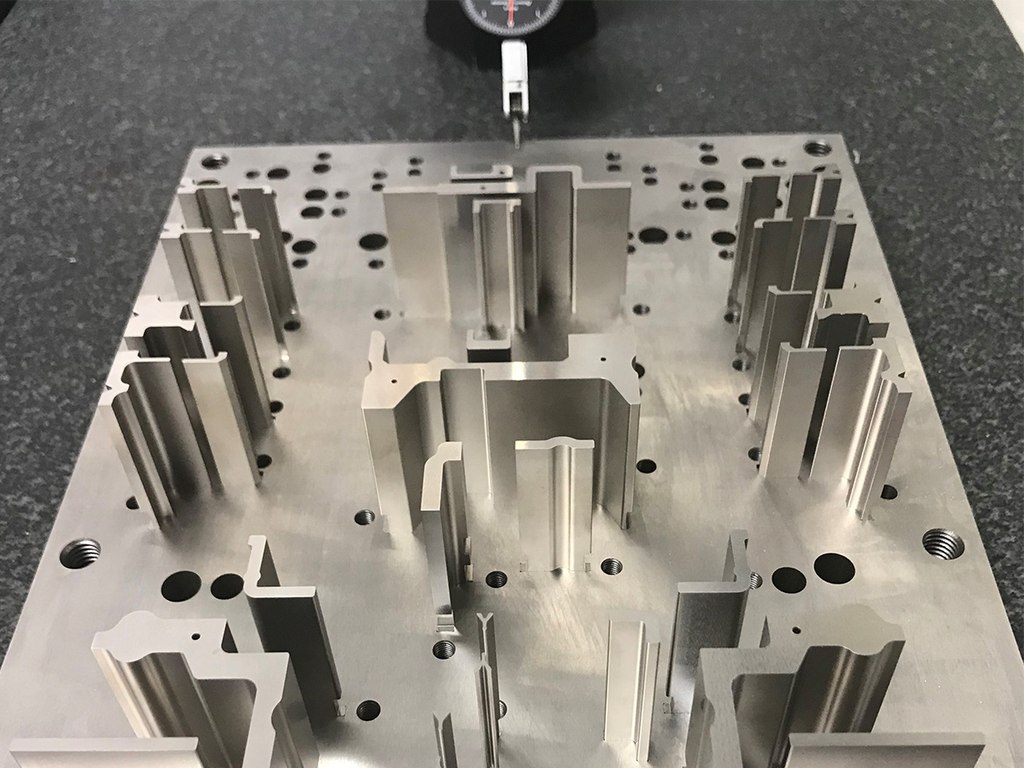

We use AGIE EDM for the very best available in EDM tolerances, Surface Finish and Surface Integrity in Tool Steel and Carbide Tooling.

Precision surface grinding of tool steel and carbide.

CNC

Machining

Close tolerance machining of small precision parts, hardened alloys and specialty tooling.

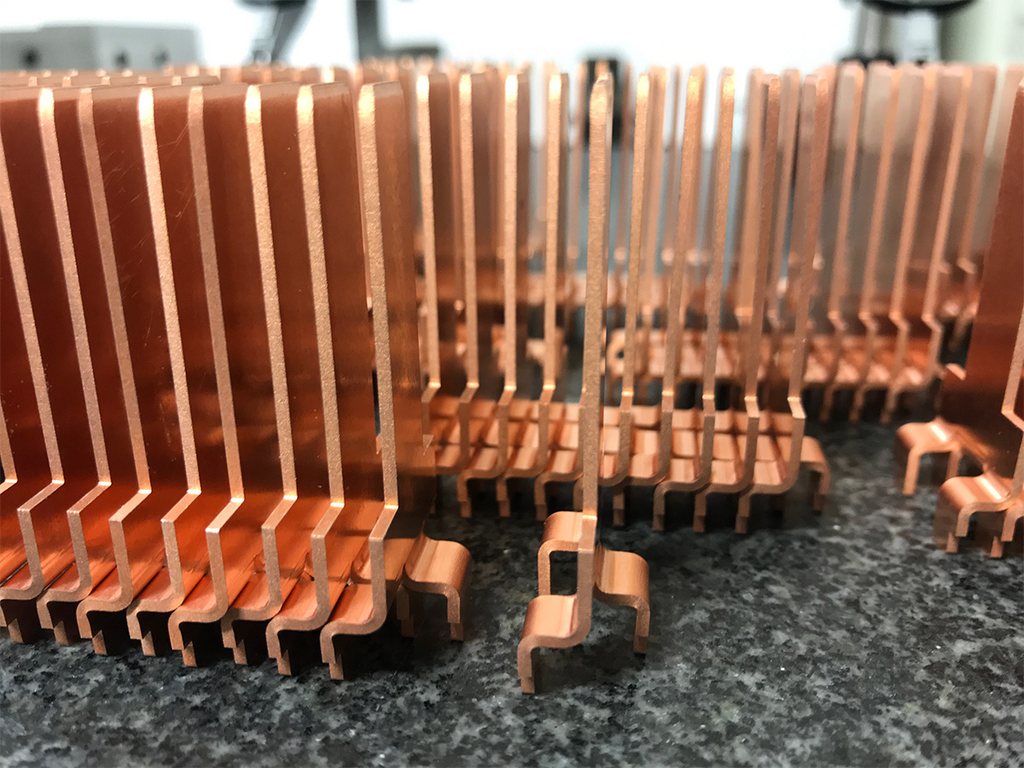

We offer precision tooling to our automated weld customers using aluminum-bronze, coated tool steels and tungsten-copper based alloys.

Prototype Electrical Terminals and Buss Bars.

Michigan Tool Technology is built on customer service, quality of product, close tolerance capability, hard work, and integrity in all that we do.

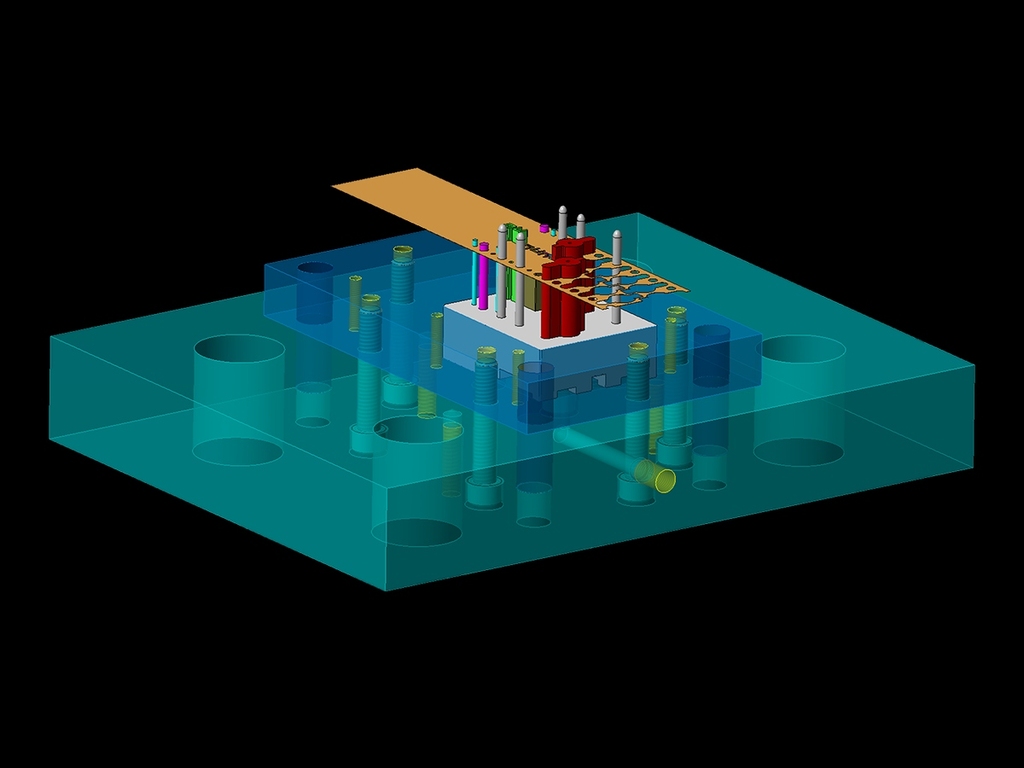

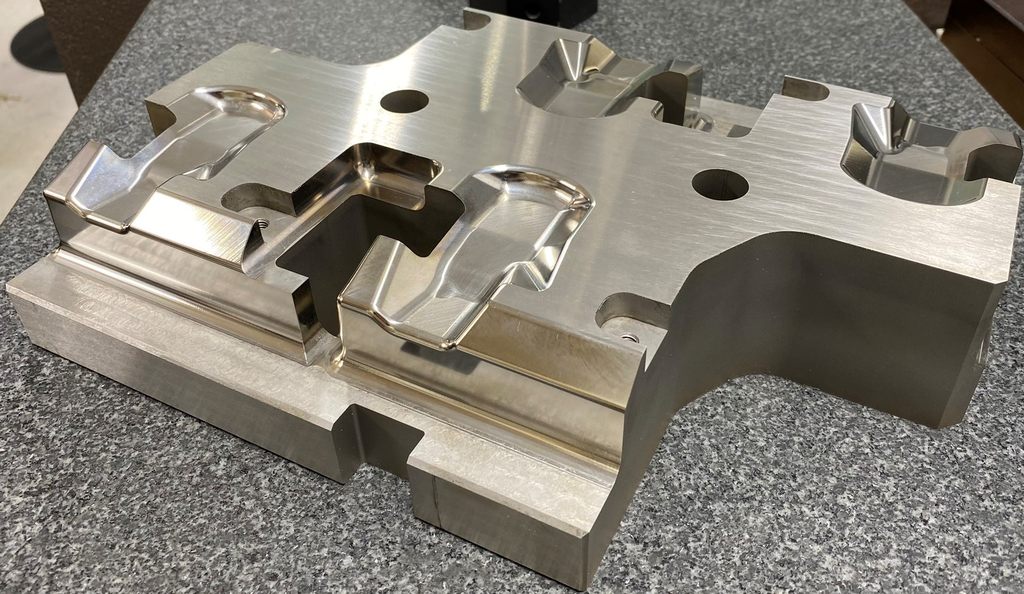

We offer design, build and project management solutions for progressive stamping dies, tooling and a variety of other tooling and design needs. Most of our experience is in the small to medium, close tolerance area of stamping and mold tooling. We apply the same skills to larger projects as well.

Our Services:

- Tool-making Our toolmakers leverage cutting-edge technology to deliver exceptional precision in every build.

- Tool Design Our design team collaborates closely with you to translate your vision into a functional and efficient tooling solution.

- Advanced Machining We utilize state-of-the-art CNC machining for unmatched accuracy and repeatability.

- Heat Treatment & Grinding Our expertise in heat treatment and precision grinding ensures your tools possess the optimal strength and durability.

- Wire & Sinker EDM We offer advanced Wire EDM and Sinker EDM capabilities for intricate tool features and complex geometries.

- Hard Milling Our hard milling services provide superior surface finishes and dimensional accuracy for demanding applications.

- CAD Design & Project Management Our team seamlessly integrates CAD design with project management, keeping you informed throughout the process.